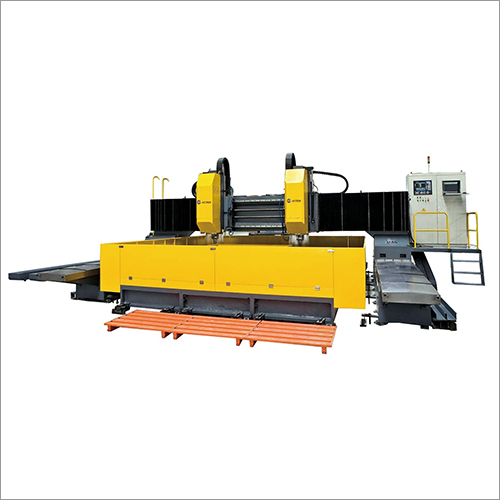

CNC Plate Drilling Machine

Product Details:

- Product Type CNC Plate Drilling Machine

- General Use Industrial

- Material Metal

- Automatic Yes

- Power Source Electric

- Warranty Yes

- Click to View more

CNC Plate Drilling Machine Price And Quantity

- 37000.00 - 39000.00 USD ($)/Unit

- 1 Unit

CNC Plate Drilling Machine Product Specifications

- Electric

- Yes

- CNC Plate Drilling Machine

- Industrial

- Metal

- Yes

CNC Plate Drilling Machine Trade Information

- Cash Advance (CA)

- 10 Unit Per Day

- 30 Days

Product Description

CNC Plate Drilling Machine is a machining process that utilizes a rotating cutting tool to produce round holes in a stationary workpiece. The holes are typically made to accommodate machine screws or bolts for assembly purposes. However, they can be used for aesthetic purposes depending on the design of the component. CNC Plate Drilling Machine is a cold cutting process that utilizes a drill bit to cut or enlarge a small circular hole within a solid workpiece.

Market: Worldwide

Specification

| Model | PZ2012 | PZ2016 | PZ3016 | ||

| Max size of work piece(mm) | one piece | 2000x1000 | 2000x1600 | 3000x1600 | |

| two piece | 1000x1000 | 1600x1000 | 1600x1500 | ||

| four piece | 1000x500 | 800x500 | 1500x800 | ||

| Max. thickness of work piece | 100mm, can overlap processing for thinner plates | ||||

| Morse taper | 4 | ||||

| Max. drilling diameter | 50mm | ||||

| Drilling spindle | Rotating speed(rpm) | 120-560( Stepless speed adjustment) | |||

| Max. feed stroke(mm) | 350 | ||||

| Motor power(kW) | 5.5 | ||||

| No. of champs | 12 | ||||

| Motor power(kW) | Servo motors | X axis | 1.3 | ||

| Y axis | 1.3 | ||||

| Z axis | 0.85 | ||||

| Weight(t) | About 5.3 | About 6.3 | About 7 | ||

| Overall dimensions(LxWxH)(m) | About 4.5x2.2x2.8 | About 4.5x2.6x2.8 | About 5.5x2.6x2.8 | ||