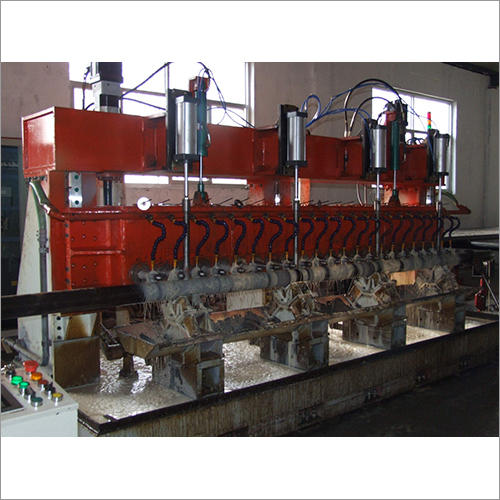

8 Axis CNC Plasma Pipe Cutting Machine For Profiles And Pipes

Product Details:

- Product Type 8 Axis CNC Plasma Pipe Cutting Machine For Profiles And Pipes

- General Use Industrial

- Material Metal

- Automatic Yes

- Power Consumption 5 Kilowatt (kW)

- Dimension (L*W*H) 7200*1350*2000 Millimeter (mm)

- Warranty Yes

- Click to View more

8 Axis CNC Plasma Pipe Cutting Machine For Profiles And Pipes Price And Quantity

- 1 Unit

- 115000.00 - 120000.00 USD ($)/Unit

8 Axis CNC Plasma Pipe Cutting Machine For Profiles And Pipes Product Specifications

- Industrial

- 8 Axis CNC Plasma Pipe Cutting Machine For Profiles And Pipes

- 5 Kilowatt (kW)

- Metal

- Yes

- Yes

- 7200*1350*2000 Millimeter (mm)

8 Axis CNC Plasma Pipe Cutting Machine For Profiles And Pipes Trade Information

- Cash Advance (CA)

- 10 Unit Per Day

- 30 Days

Product Description

8 Axis CNC Plasma Pipe Cutting Machine For Profiles And Pipes is a melting process in which a jet of ionized gas at temperatures above is used to melt and expel material from the cut. During the process, an electric arc is struck between an electrode and the workpiece. 8 Axis CNC Plasma Pipe Cutting Machine For Profiles And Pipes is a magnetized machine with a solenoid coil which is driven by an electric motor. The steel template of any shape is guided by its edge cut to the desired profile with the help of a cutting torch.

Market: Worldwide

Specification

| Model | 8 axis all profiles and pipes CNC cutting machine |

| Cutting range | 6m 9m 12m ( customized ) |

| Machine size | 7200x1350x2000mm (customized ) |

| Cutting method | Flame/plasma |

| Cutting thickness | Flame:6-60mm Plasma: standard 2-14mm |

| Flame cutting speed | 20-700mm/min |

| Plasma cutting speed | 500-3500mm/min |

| Control system | Advantech industrial computer |

| Plasma Max. hole thickness | 14mm |

| Plasma Max. edge cutting thickness | 18mm |

| Plasma torch crash protection system | Yes |

| Driving motor | Servo |

| Software | KASRY pipe apply software |

| Working condition | |

| Working pressure of compressed gas | Above 7mpa |

| Require gas flow of plasma | 4500L/H |

| Working environment | Ventilation ,no concussion |

| Power wattage | 5KW |

| Types of gas | Acetylene propane |