5 Axis CNC Pipe Plasma Cutting Machine

Product Details:

- Product Type 5 Axis CNC Pipe Plasma Cutting Machine

- General Use Industrial

- Material Metal

- Automatic Yes

- Power Source Electric

- Power Consumption 5 Kilowatt (kW)

- Dimension (L*W*H) 7800*1800*1650 Millimeter (mm)

- Click to View more

5 Axis CNC Pipe Plasma Cutting Machine Price And Quantity

- 1 Unit

- 190000.00 - 195000.00 USD ($)/Unit

5 Axis CNC Pipe Plasma Cutting Machine Product Specifications

- 5 Axis CNC Pipe Plasma Cutting Machine

- Industrial

- 5 Kilowatt (kW)

- Electric

- Yes

- 7800*1800*1650 Millimeter (mm)

- Yes

- Metal

5 Axis CNC Pipe Plasma Cutting Machine Trade Information

- Cash Advance (CA)

- 10 Unit Per Day

- 30 Days

Product Description

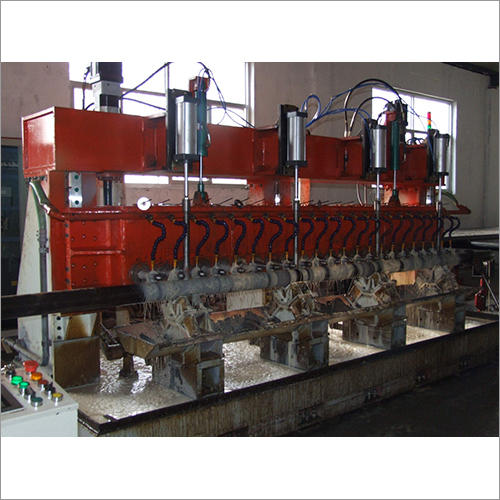

5 Axis CNC Pipe Plasma Cutting Machine uses a plasma cutter to cut thin to thick metals along a multi-axis grid. The CNC method provides an advantage over handheld plasma cutting tools due to the cut being programmed and controlled by a computer instead of human motion. 5 Axis CNC Pipe Plasma Cutting Machine is used for cutting the metal. It is one of the most widely used techniques to cut thick metal plates but is also available for sheet metal.

Market: Worldwide

Specification

| Mode | XY Round pipe CNC cutting machine |

| Cutting range | 6m 9m 12m (customized ) |

| Machine size | 7800x1800x1650mm (customized ) |

| Cutting method | Flame/plasma |

| Flame cutting speed | 20-700mm/min |

| Plasma cutting speed | 500-3500mm/min or upon the plasma power |

| Control system | Advantech industrial computer |

| Plasma Max. hole thickness | 14mm |

| Plasma Max. edge cutting thickness | 18mm |

| Plasma torch anti-collision system | yes |

| Plasma bevel | 6-14mm |

| Driving mode | Servo |

| Software | KASRY pipe apply software |

| Working condition | |

| Working pressure of compressed gas | Above 7mpa |

| Required gas flow of plasma | 4500L/H |

| Working environment | Ventilation, no concussion |

| Power wattage | 5KW |

| Types of gas | Acetylene propane |